The Architect’s Role in Reducing Embodied Carbon in Data Centres 19 Dec 2025

By Alex Soto

With the expansion of the digital economy, data centres have emerged as essential infrastructure, but they are still some of the most carbon-intensive types of buildings. Whilst the sector is making great strides in improving operational efficiency through investment in renewable energy translated into Power Purchase Agreements (PPAs) and Renewable Energy Guarantees of Origin (REGOs); and deploying the next generation of cooling systems, the next frontier is embodied carbon: the emissions generated through the extraction, manufacturing, transport and disposal of materials. This is where architects have real influence and responsibility.

Architects influence the overall carbon impact through their design decisions. Data centres typically utilise carbon-intensive traditional materials such as steel, concrete, glass and aluminium for durability, cost-effective, resilient designs that facilitate construction procurement and speed to market. A trend that is predicted to accelerate with mass AI deployment. Alternative timber structures are still seen as niche projects, as they can bring challenges associated with insurance, the need for specialised trades, and a likely impact to program and costs to mainstream data centre projects. Challenges that will take some time for the industry to overcome.

It is far from a gloom and doom scenario for embodied carbon mitigation, as early design decisions can steer the direction of a data centre project’s carbon footprint. From concept design, discussions with clients and collaboration with engineers and suppliers allow for whole-life carbon assessments, ensuring that performance and sustainability targets are embedded before construction begins. A key task is for the project team is to design out waste at every stage: By starting with simple shapes that lead to standard construction details, optimising façade grids, reducing over specification, incorporating modular elements that can be dismantled and recycled at end of life. By fostering circularity with pre-demolition audits – If aluminium and glass are dismantled from an existing façade for example, they are take-back schemes available in the UK ready to feed into material banks for reuse or to feed into post-consumer recycled content for another curtainwall system manufacturer. Therefore, the material loop is closed.

The type of energy used to produce materials is important because the energy mix used in material manufacturing has a major influence on upfront embodied carbon (Stages A1 to A3 in life cycle analysis). Such is the case for sandwich metal façade panels with steel layers and mineral insulation cores are both highly energy-intensive products specified for data centre envelopes.

Manufacturers that use renewable electricity in production, as several UK and European suppliers now do, can cut emissions by more than 40% compared to fossil fuel-based manufacturing. Architects who engage directly with their supply chains and request Environmental Product Declarations (EPDs) can leverage procurement power to reward low-carbon manufacturing and advance clients ESG goals and UK’s 2050 net-zero ambitions.

To accelerate decarbonisation across the data centre sector, leadership must extend beyond purely operational efficiency to the full life cycle of materials.

Architects and designers can help data centre clients achieve measurable embodied carbon reductions and future-proof assets against tightening environmental targets by integrating embodied carbon awareness and benchmarking into the design process. Carbon literacy, agency and agility to keep up with program demands are essential skills to look for in design teams to engage with supply chains and to accelerate a path to industry decarbonisation.

Let us keep the momentum going

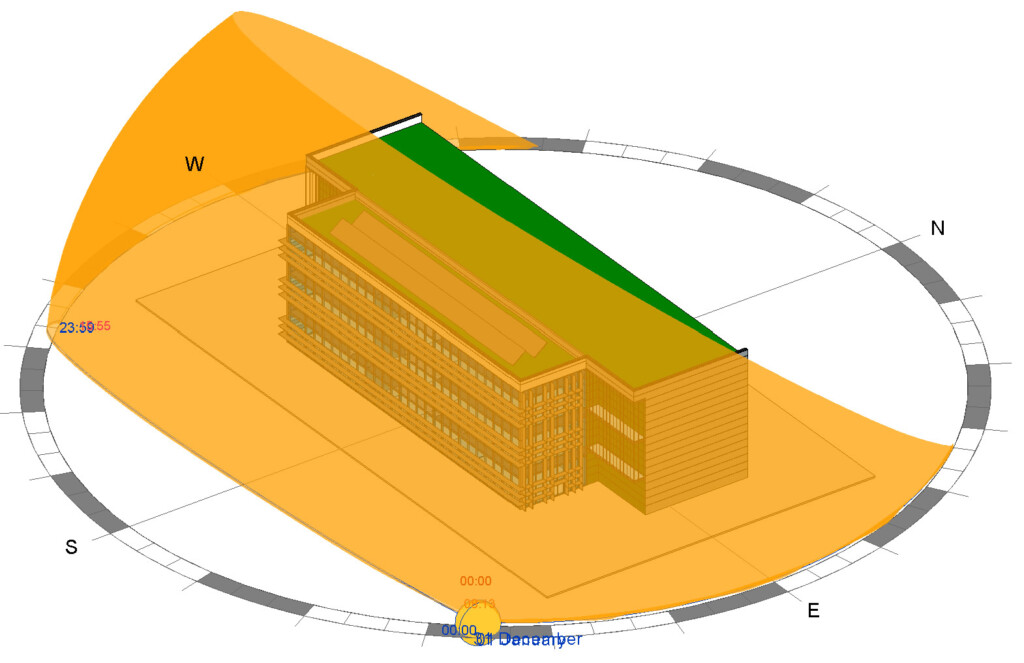

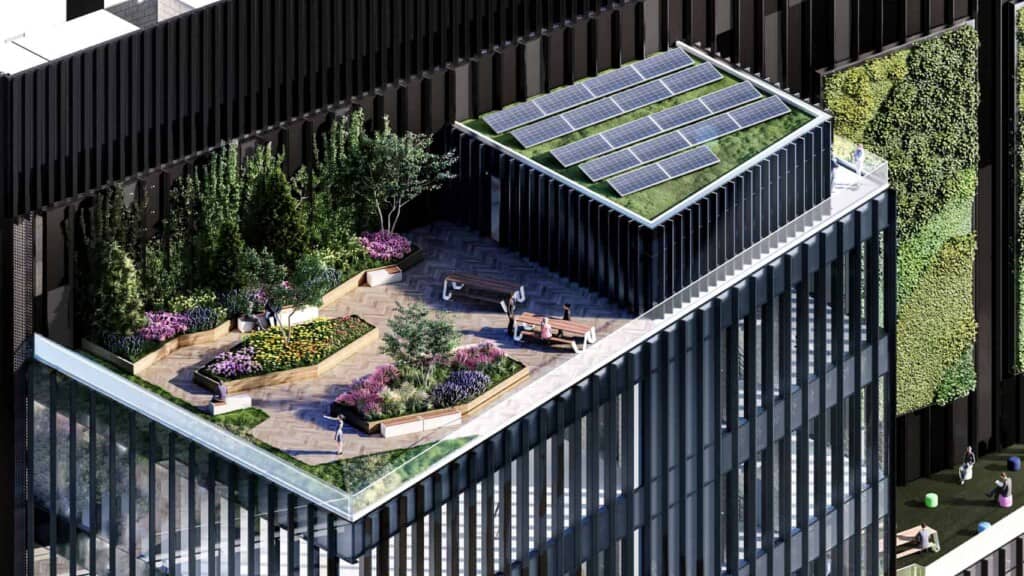

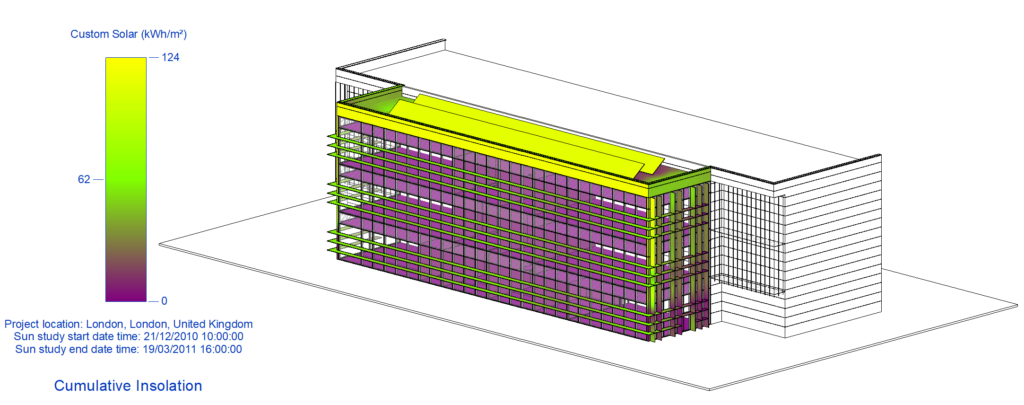

Glazing ratios and solar shading devices designed to suit solar orientation ensure the building façade becomes more resilient to excessive heat gains and losses.

Glazing ratios and solar shading devices designed to suit solar orientation ensure the building façade becomes more resilient to excessive heat gains and losses.